Advance Steel features

Facilitate collaboration between engineers, detailers and fabricators to create information-rich models for steel design and fabrication.

Parametric steel connections

Access a library of pre-designed, customisable connections that can save time, increase accuracy, ensure compliance and improve collaboration in the modeling process. Users can adjust the dimensions, materials, and other parameters to fit their specific project requirements.

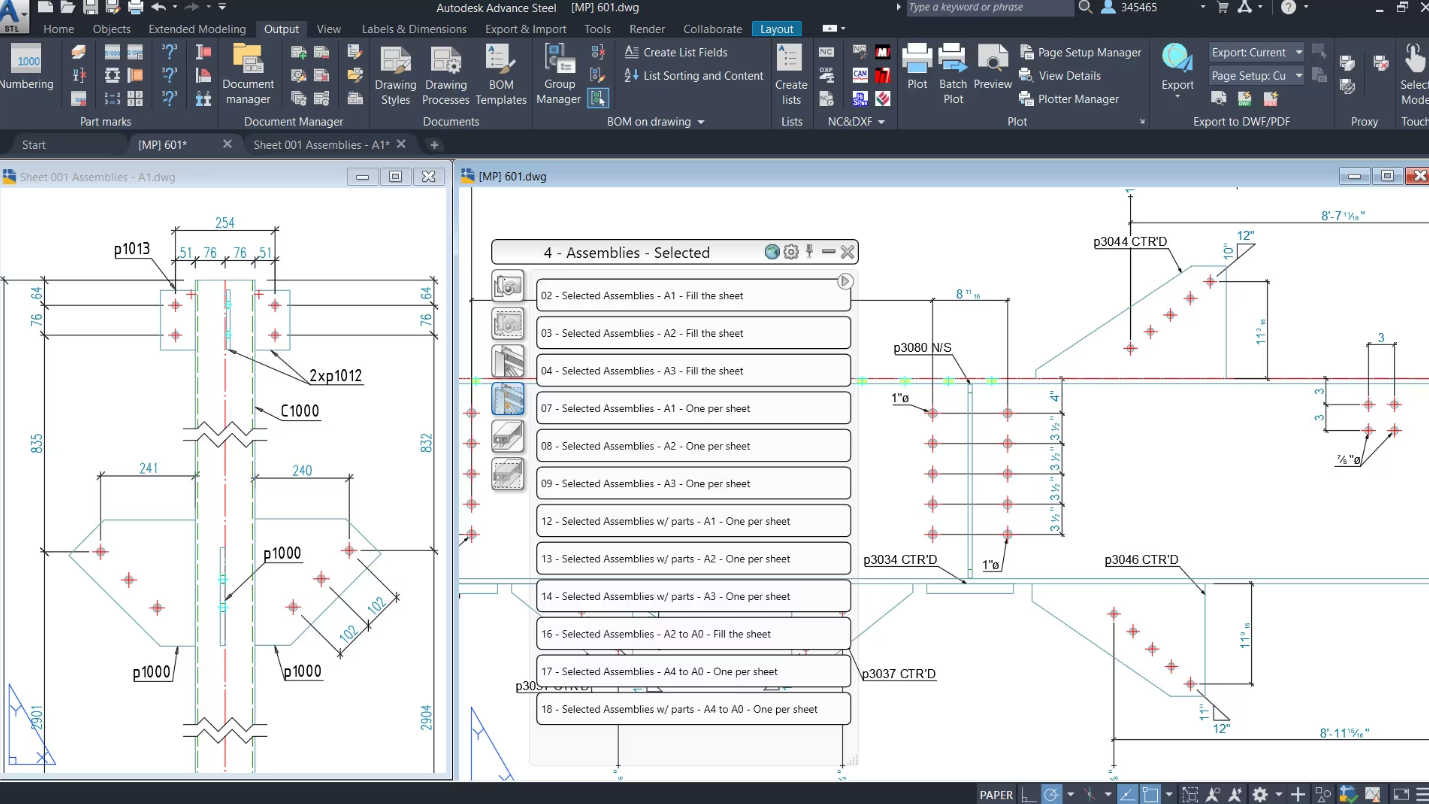

Create accurate drawings and data for fabrication

Create accurate fabrication drawings and data and automatically generate and update steel fabrication deliverables. Create model-driven shop deliverables and NC files for fabrication, ensuring accuracy and efficiency. Changes made to the model are automatically reflected in the deliverables, reducing the need for manual updates and improving collaboration between stakeholders.

Connect workflows with integrated tools in the AEC Collection

Advance Steel can integrate with several Autodesk software programs, including Revit, AutoCAD, Navisworks, Robot Structural Analysis, and Autodesk Docs, to share, refine, and synchronise design data. The integration allows for a collaborative design process, reducing errors and inconsistencies, and improving project delivery efficiency. The software's ability to connect steel detailing and design data to BIM and CAD workflows can further enhance the design and detailing process.

Additional features

Parametric steel connections - With a customisable library of pre-built steel connections, Advance Steel enables faster, more efficient, and accurate modelling.

Stairs and cage ladders - Allows for the rapid and precise discovery and modeling of non-structural building components.

Sheet metal and folded plate work - Create 3D folded elements of any sheet metal shape faster.

Dynamo Extension for Advance Steel - Utilising Dynamo's visual programming language enables the creation of complex and parametrically driven geometries for intricate structures.

Code checking and design validation - Check for compliance and validate steel connections against AISC standards.

Propagation of steel connections - Automated connection propagation reduces tedious work and guarantees the precise placement of steel connections.

General arrangement drawings - Set drawing styles and camera defaults and use general arrangement drawings to document and clarify design intent for on-site construction.

Steel shop drawings - Automatically generate detailed and annotated fabrication-ready drawing sets.

Numerical Control (NC) data - Generate detailed fabrication datasets to direct and drive CNC workshop machines.

Hide or show detailed parts - Isolate parts and assemblies already detailed for fabrication.

Bills of Materials - Automatically generate BOMs from modelled element data for use in spreadsheets and reporting.

Drawing update with revision - Use revision clouds to reduce time spent tracking modifications to shop drawings.

Bi-directional link with Revit - Advance Steel allows for seamless synchronisation of model updates with Revit, ensuring tracking of design changes and preventing data loss during project evolution.

Robot Structural Analysis interoperability - Advance Steel allows for the transfer of structural analysis data, including calculations, between Robot Structural Analysis and itself - promoting the synchronisation of design, analysis and detailing workflows.

Autodesk Docs interoperability - With the compare tool in Autodesk Docs (previously BIM 360 Docs), Advance Steel enables the monitoring of progress and evaluation of change impacts.

AutoCAD Plant 3D interoperability - Use AutoCAD Plant 3D and Advance Steel together in the AEC Collection to connect and sync fabrication to plant design.

MIS software interoperability - Export data via KISS, XML or IFC with MIS software.

Customised settings import - Save time by importing your customised settings when upgrading to new versions of Advance Steel.

Open and flexible API - Advance Steel offers APIs that enable software developers to enhance and expand its functionality by managing data, connecting to other software and creating customised tools.

IFC abilities - Import or export a 3D model to an IFC 2x3 file.

View native drawings in AutoCAD - Improve data accessibility by viewing Advance Steel drawings with object enabler.

Navisworks interoperability - Integrate into Navisworks to improve quantification, simulation, review and model coordination.

Shared views - Facilitate design collaboration through shared views, allowing progress to be displayed to stakeholders within or outside an organization.

Attach a point cloud - Enable designing within site context and existing conditions by integrating laser-scanned point cloud data with snap-to functionality.