Romar streamlines production with Autodesk Fusion and Netfabb

Romar provide advanced manufacturing and processing solutions for a wide range of highly regulated industries including aerospace, aeronautical, medical, defence and automotive applications.

The challenge

Since 1968, Romar has provided manufacturing solutions to highly regulated industries including aerospace, aeronautical and medical. Romar’s challenge was the integration of their various design platforms into one software suite. The team had previously employed a variety of software for FEA, CAD and CAM and needed a solution that would enhance interoperability, integration, and efficiency, with 3D metal printing capability.

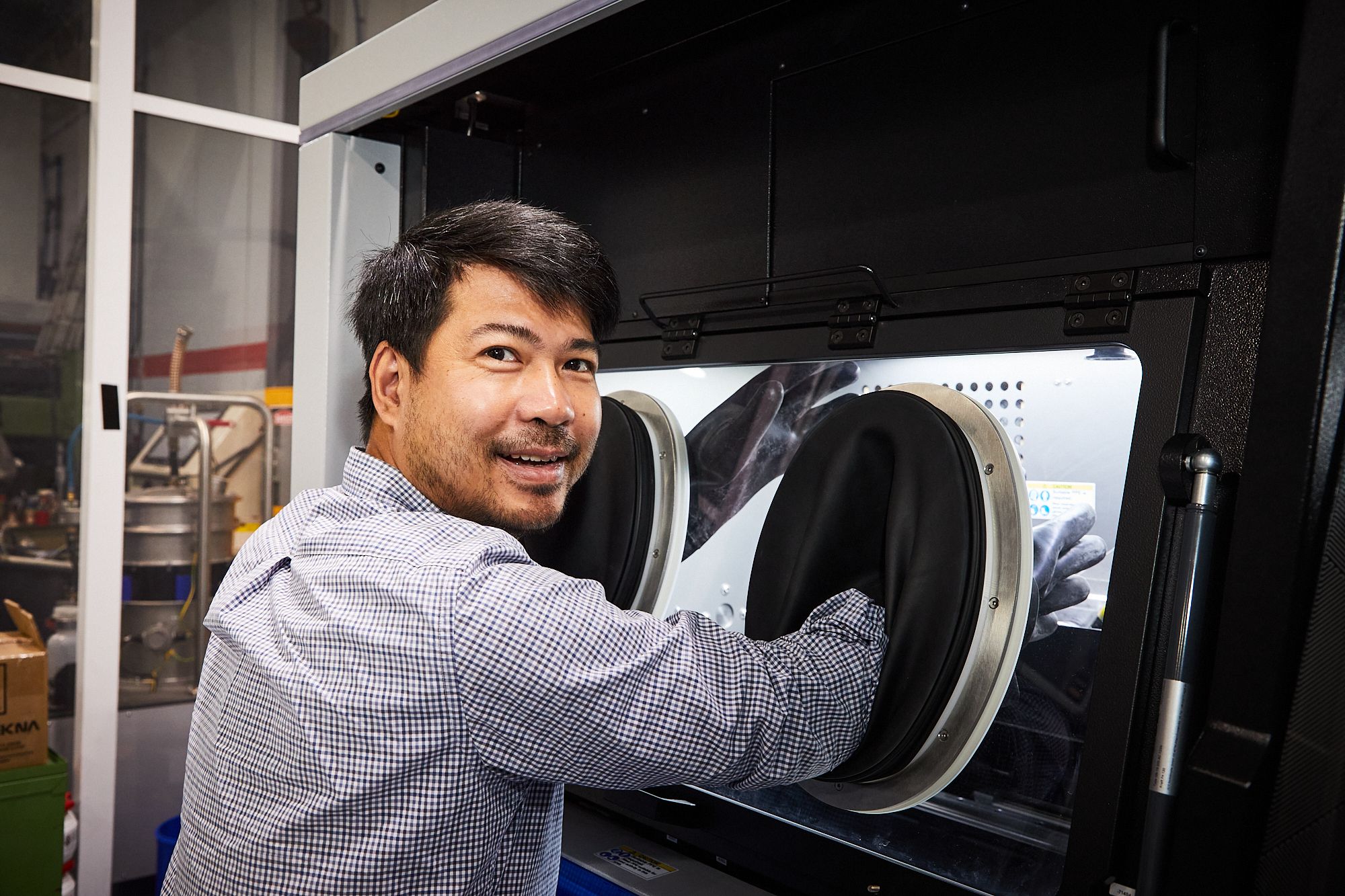

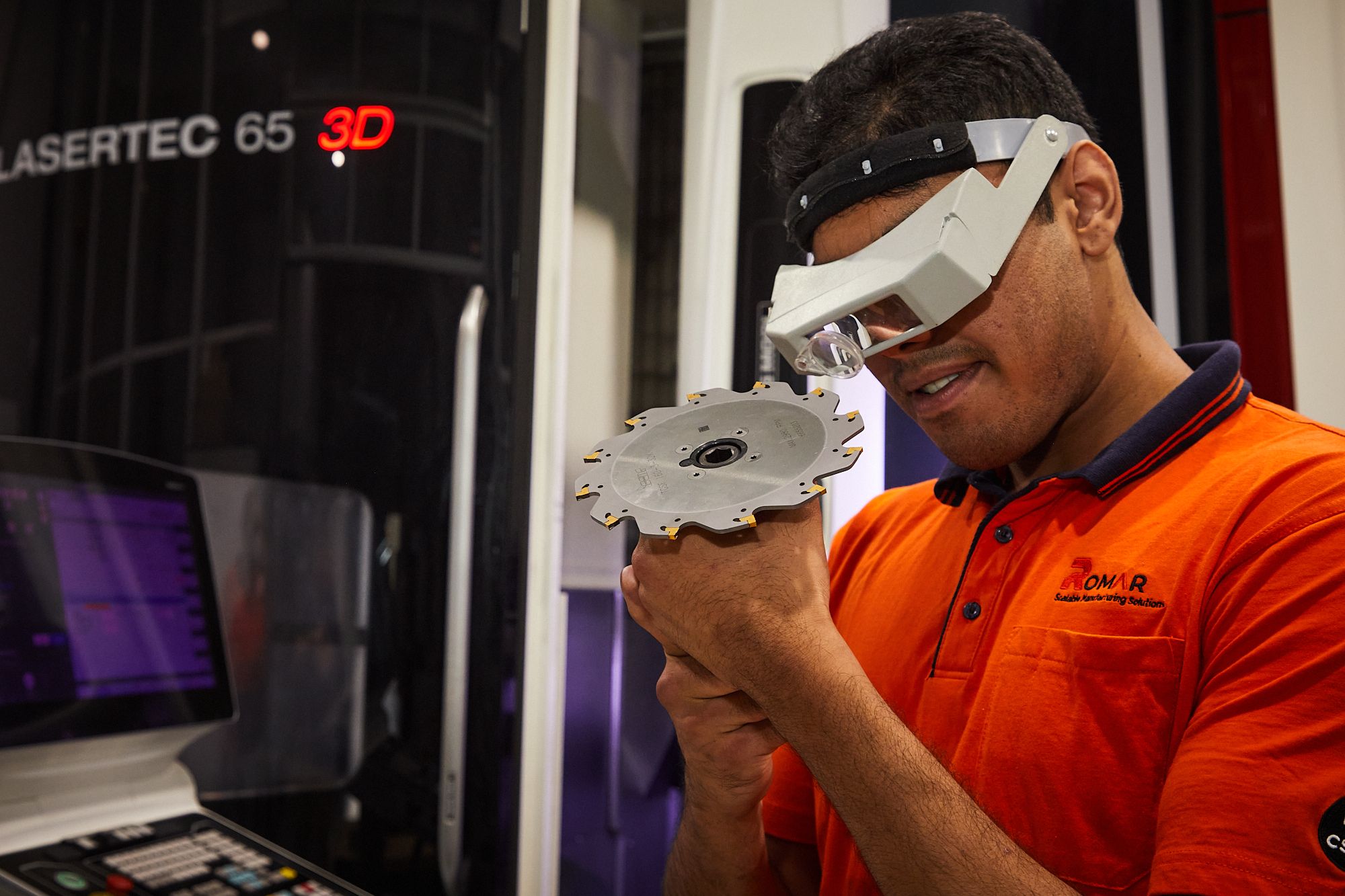

Although Romar has conducted 3D metal printing on their Lasertec 65 Hybrid since 2016, the acquisition of a GE M2 3D metal printer has expanded their offering to laser powder bed fusion for material parameter development in multiple 3D metal printing modes. A unique service in the Australian market, currently only seen in academia.

“A big portion of our future is in material development” explains Steve Milanoski, Head of Advanced Manufacturing. Romar’s evolution into material development required software with high degrees of innovation, customisation and support.

Project Location:

Sydney

Software Used:

- Autodesk Fusion

- Autodesk Netfabb

Project goals

To shift to an integrated software approach, Romar needed a solution that could coordinate teams and streamline design-to-manufacture without sacrificing operational quality or simulation fidelity. Employing software that allowed them to remain competitive and agile was another critical consideration.

“Our competitors have a huge financial advantage; however, we can move quickly, and they can’t. To move quickly, we can’t be jumping across platforms, the team has to be on the same page.”

Of particular importance was material parameter development for 3D metal printing. Which was ‘vital’ for market expansion and would give Romar an advantage few competitors could match.

“Romar has a history of pivoting successfully, we’ve gone from toolmakers, to roboticists, to injection moulders to biomedical manufacturers. When printing for space, I need to start from first principles and develop materials that will optimise print speed and mechanical performance, without reinventing the wheel.”

“Everybody was on different solutions and there was no central repository for information. Having Scott sit down with us each day, give us three hours of training and one hour of back and forth, just catapulted us into adoption.”

Steve Milanoski – Head of Advanced Manufacturing

The solution

To address the challenge of multiple platforms, Cadpro assisted Romar to implement Autodesk Fusion as their predominant design and advanced manufacturing software. Scott Moyse (Cadpro), undertook Autodesk Fusion training with Romar engineers, focusing on best practice for modelling, 3D surfacing, five-axis CAM and data management. He also configured Fusion Team to boost Romar’s collaborative capability.

“Everybody was on different solutions and there was no central repository for information. Having Scott sit down with us each day, give us three hours of training and one hour of back and forth, just catapulted us into adoption.”

Cadpro also supplied Romar with Netfabb as an ideal solution for material development for 3D metal printing, Steve explains. “These are brand-new things we are bringing in; we needed a software solution that could adapt with us and grow at the same fast pace. But you’re only as good as the support you get, so having Scott and good customer service is what propelled us.”

Business outcomes

Shifting to Autodesk Fusion and a holistic approach to software management produced significant cost and time savings in comparison to Romar’s previous model. Autodesk Fusion has provided a central repository for 3D data in the cloud, eliminated the process of emailing models and improved efficiency and collaboration within their team. Simultaneously, Cadpro training has allowed staff to upskill significantly:

“We have an engineer who’s never used CAM and is now doing five-axis machining with a post we developed in-house. The alternative is spending huge amounts on the post alone and another software.”

Netfabb has seen Romar successfully expand their scope of additive offerings and increase productivity, removing the need to source materials elsewhere; “The strength of Netfabb lies in its ability to rapidly develop bespoke material parameters for 3D metal printing. Within two weeks, we were printing material above standard industry specifications, verified with our internal testing capabilities.”

The Result:

Romar’s Autodesk suite has streamlined their manufacturing process, enabled much greater efficiency, and propelled their ability to get product to market quickly.

“How many people are conducting design, analysis, manufacture and soon inspection, with one software suite? The fact that I never have to move models across programs, have control over post-processors and machine interfaces, is well worth it considering the alternatives with cost and flexibility.”

The ability to conduct material parameter development for 3D metal printing has bolstered Romar’s position as an agile and competitive player in advanced manufacturing for mission-critical markets, and Cadpro’s support has provided greater assurance as they develop their manufacturing prowess.

“We’re not just building products, we’re building a factory and we need reliable solutions, we can’t afford a science experiment between here and success. We have to be as accurate as possible the first time, which is why we went with Cadpro.”

Learn more about Romar